The Automatic Scan System for Your Logistics

Automated capture of pallets, roll cages, NVE and SSCC codes when passing through

Introduction

A modern scan system for goods receipt is becoming increasingly important in today's logistics. Goods receipt is one of the most critical areas in the material flow: Here it is decided whether deliveries are documented correctly or whether errors, time losses and manual rework occur. Many companies still rely on handheld scanners to capture NVE labels – a process that depends heavily on the operator and quickly reaches its limits with soiled, damaged or poorly positioned labels.

With our scan system, this process is fully automated. The camera-based pass-through system recognizes every delivery when it passes, evaluates NVE and SSCC labels in real time and automatically matches the data with the loading list. This creates a faster, more reliable and digitally documented goods flow in goods receipt and throughout logistics.

Challenges in Today's Goods Receipt

In many logistics centers, goods control is still performed manually. Staff scan NVE and SSCC labels individually with handheld scanners or walk through a scanner tunnel where classic barcode handheld scanners or simple barcode recognition systems are used.

This manual barcode capture is time-consuming and prone to disruption: Damaged labels, poor lighting, changing staff, stressful situations and operator errors regularly lead to incorrect or missing captures.

Another problem arises when several load carriers are pushed through goods receipt simultaneously. For example, if there is only one barcode on two pallets, classic scan systems do not recognize this error. Only the existing code is captured – the second load carrier remains unregistered. This leads to inventory errors, incorrect quantity records and lower scan rates.

In addition, conventional systems do not recognize when barcodes are completely missing – for example because labels have fallen off or were never attached. Quantity counting of load carriers is also often done manually and is therefore error-prone.

This combination of manual capture and lack of transparency leads to discrepancies, incorrect postings and unclear goods receipts.

Another weakness of classic barcode or handheld scanner systems is the lack of direction recognition. The systems do not know whether goods are being put into or taken out of storage. Some companies try to address this with light barriers, but in complex logistics environments with multiple gates, variable routes or parallel goods flows, these solutions are often unreliable and prone to false triggers.

Typical Challenges in Goods Receipt

ScanGate: Automated Goods Control with Our Scan System

The PixelEdge Scan System automates the complete goods control process and eliminates the weaknesses of classic handheld scanners, scanner tunnels and static barcode recognition systems. The smart scan system recognizes every pallet and every load carrier fully automatically when passing through – without stopping and without operator interaction.

NVE and SSCC labels are reliably recognized even when they are soiled, rotated, partially obscured or poorly positioned. At the same time, the AI identifies each individual load carrier and immediately reports when a label is missing, has fallen off or when only one label exists for multiple pallets. This prevents inventory errors, quantity discrepancies and incorrect scan rates.

All captured codes are matched in real time with the expected loading list. Missing NVEs, duplicate codes, unclear positions or incomplete deliveries are detected immediately and displayed clearly. In addition, ScanGate documents every pass with images, so discrepancies, claims and goods receipts are transparent and traceable at any time.

Unlike classic systems, ScanGate also automatically recognizes the direction of movement of the goods – without light barriers, which often trigger unreliably in complex logistics environments. The system knows exactly whether goods are being put into or taken out of storage.

Advantages over Classic Scanners

Digital Loading List Verification in Real Time

A central advantage of the scan system is the fully automated verification against the stored loading list. While load carriers pass through the gate, the system captures every NVE and SSCC number and immediately matches it with the information from the ERP, WMS or customer system. This completely eliminates the manual comparison between paper lists and actual delivery.

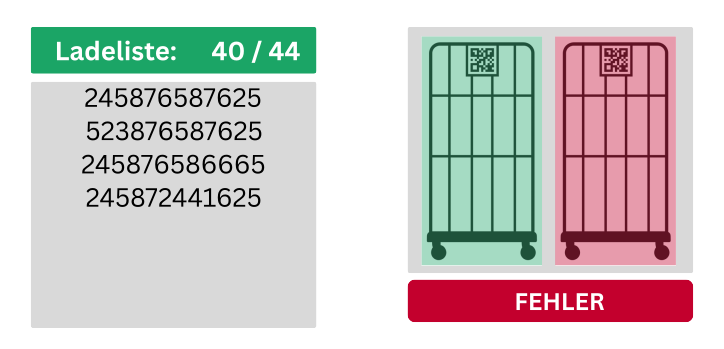

The schematic representation also clearly shows: If a barcode is missing or unreadable, ScanGate immediately marks the affected load carrier in red. This allows the user to recognize incomplete or faulty deliveries during the process – long before they lead to incorrect postings, conflicts or claims.

Via the intuitive web HMI, the user can see the current progress status of the loading at any time: Which positions have already been captured, which are still missing and whether unexpected or additional load carriers have passed through the gate.

Automated Verification with ERP and WMS Systems

Application Areas and Conclusion

The PixelEdge ScanGate is suitable wherever goods flows need to be captured reliably and quickly – both at goods receipt and goods dispatch. Typical application areas are central logistics zones, cross-docking areas, production deliveries and e-commerce and fulfillment processes. Especially in environments with high throughput or high error cost risk, the system fully demonstrates its advantages.

In summary, ScanGate enables modern, automated and error-free goods control. The process becomes faster, more stable and fully digitally documented. Companies benefit from a significant reduction in manual work, less rework and higher process reliability in the entire goods receipt and goods dispatch area.

Frequently Asked Questions about ScanGate

What is the PixelEdge ScanGate and what is it used for? +

The PixelEdge ScanGate is an AI-powered pass-through scanner system that automates the entire goods receipt and goods dispatch process. It recognizes load carriers when passing through, reads NVE and SSCC labels and automatically matches all data with the digital loading list. This completely eliminates manual scanning and the process becomes faster, more secure and digitally documented.

How does ScanGate differ from classic handheld scanners or scanner tunnels? +

Handheld scanners and scanner tunnels only work reliably when labels are clean, correctly positioned and clearly visible. ScanGate works with image and AI-based recognition and detects barcodes even with soiling, damage, poor lighting or partial coverage. It also checks quantities, missing labels and implausible deliveries – something handheld scanners cannot do.

Does ScanGate also capture damaged, soiled or partially obscured barcodes? +

Yes. The integrated AI recognizes NVE and SSCC codes even in difficult situations: rotated, soiled, damaged, poorly positioned or partially obscured. Missing or duplicate labels are automatically detected and reported – including visual marking in the HMI.

How does digital loading list verification work with ScanGate? +

All captured codes are matched in real time with the loading list from the ERP, WMS or customer system. Missing pallets, implausible deliveries or quantity discrepancies are displayed immediately. The user always sees in the HMI how far the loading or unloading is completed.

Does ScanGate also detect missing labels or multiple pallets with only one code? +

Yes – that is one of the biggest advantages. ScanGate recognizes each individual load carrier and immediately reports when a label has fallen off or when only one barcode exists for multiple pallets. This prevents inventory errors and incorrect scan rates.

Can ScanGate detect direction (inbound vs. outbound)? +

Yes. Direction is automatically recognized through AI-based movement analysis – without unreliable light barriers. The system always knows whether goods are being put into or taken out of storage.

How does ScanGate integrate with existing ERP or WMS systems? +

Integration is via modern REST APIs or standardized data interfaces. ScanGate can communicate with SAP, Blue Yonder, Infor, Microsoft Dynamics, PSI, Körber, Wamas and all common systems. Data is transmitted and synchronized live.

How does ScanGate work with Edge.Trace? +

All captured data and images are automatically transferred to Edge.Trace and stored there in an audit-proof manner, visualized and evaluated. Users see every pass as an image sequence, including errors, missing labels and discrepancies with the loading list.

Are the captured images stored? +

Yes. Every pass is documented with images. This data supports claim clarification, audits and internal process control. Storage can be local or cloud-based.

How reliably does ScanGate work in daylight, at night or against backlight? +

ScanGate uses optimized lighting, industrial camera technology and AI-based image analysis. Capture is therefore independent of daylight, shadows, backlight or night operation.

How long does installation of a ScanGate take? +

Typically the system is installed within one day. Complete commissioning including interface integration usually takes 1–3 days.

What does a ScanGate cost? +

Costs depend on configuration, throughput, required interfaces and installation effort. Companies typically amortize the investment within a few months through time savings, fewer errors and better process control.

Is ScanGate suitable for high throughput volumes? +

Yes. Especially with high volumes – e.g. central warehouses, food logistics, e-commerce – the system achieves significant efficiency gains. Multiple load carriers per pass are recognized without any problems.

How robust is the system? Can it be used outdoors? +

ScanGate is available in weather-resistant IP55 design and is therefore suitable for outdoor areas, ramps and loading docks.

We're ready when you are.

Discover solutions that inspire. Get informed now and become a partner – automated scan system for your goods receipt.